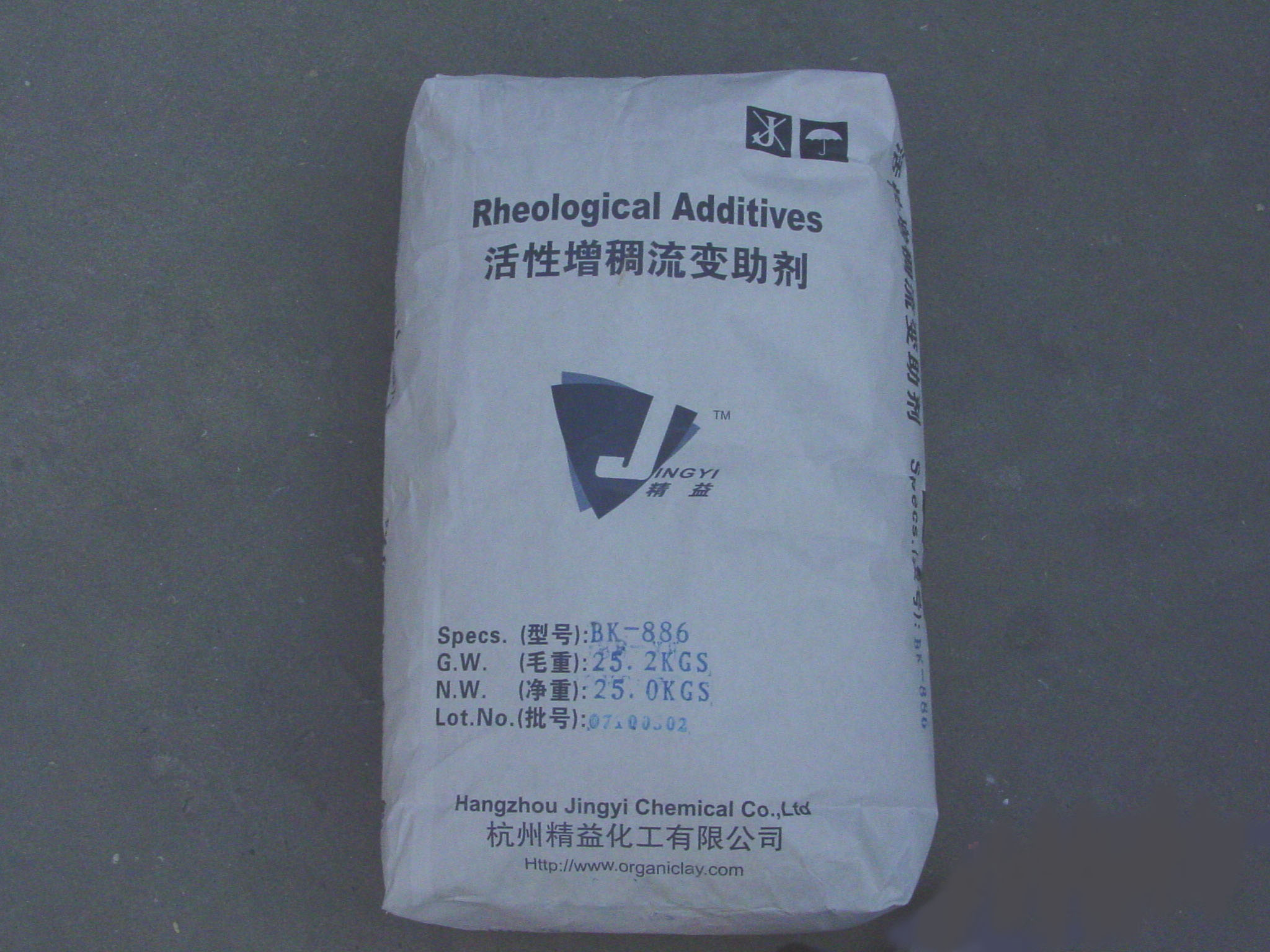

BK®-886

is an organoclay (tetraallkyl ammonium bentonite) for solvent-based systems of

low to medium polarity.

1. Advantages:

2. Typical Properties:

| Color | Appearance | Density |

Moisture (@105℃,2hrs) |

Fineness through 200 mesh |

Loss on Ignition ( @1000℃ ) |

|

Light White |

Free Flowing Powder | 1.67g/cm3 | ≤3.5% | ≥98% | ≤35% |

| ●Acrylic paint | ●Solvent epoxy paint |

| ●Alkyd paint | ●Zinc-rich paint |

| ●Baking paint | ●Nitro lacquer |

| ●Foundry paint | ●Adhesive |

| ●Polyester paint | ●Lubricating grease |

| ●Road paint | ●Cosmetics |

| ●Silica paint | ●Inks |

4. Incorportions:

BK®-886 belongs to the conventional type of organoclay group, which requires mechanical

energy, shear forces applied with a goods dispersion equipment, and a chemical

(polar) activator to reach the proper level of delamination of

the organoclay platelet

stacks.

Polar Activator: Dosage of polar activator ( such as propylene carbonate, 95%ethanol ,

acetone or 95% methanol) is 30%-60% by weight of BK®-886.

It is

always recommended to determine the proper level of addition by experiment.

Either defect or excess of chemical activator would result in poorer viscosity

development.

5. Recommended

Levels:

The amount of BK®-886 rheological additive required depends upon the type of

organic system and the degree of thickening or other properties desired.

Addition levels are typically between 0.2%-2.0% based on the total formulation

weight.